产品展示

首页 > 产品展示

TPEE Application:

1. Auto Parts

TPEE has excellent resistance to (hot) oil, excellent (high temperature) curve flex fatigue performance, wear resistance, high strength and high toughness.

TPEE produced by various types of car parts with a flexible system of rubber parts is more than excellent performance, the higher temperature levels, better low temperature properties, especially the fatigue performance of TPEE other elastomers can not match.

Mainly used in auto parts: CVJ dust cover, ball dust cover, cantilever jacket, tie and jacket, and other dust cover jacket; ball wrist; air hose (engine intake air duct) airbags, seat belts department (distribution) parts, auto headlamps, auto door locks, satellite antenna clamp, door seals, shock by grinding plate, muffler gear, stopper, plug, window seat shock absorber, reducing shock chassis, chassis stoning-resistant coatings.

2. Electrical and Electronic

Excellent aging resistance and at low temperature physical properties of good performance, so TPEE been widely used in electrical and electronic industries, such as: wireless communications equipment antennas jacket, muffler gear drive system, electric soft cover, remote control buttons, etc. .

3. Sports Equipment

TPEE in a wide temperature range to achieve a good balance between strength and flexibility, and excellent impact resistance, fatigue resistance and UV resistance, making it very suitable for the production of ski cover, ski boot straps, golf ball and other sports equipment

4. Fiber optic cable system

TPEE for fiber-optic cable system is mainly manifested in the flexibility and high tear strength, chemical resistance, heat resistance, flame retardant, easy to dye, to seal from dust and liquid long-term role. TPEE has excellent tear strength, the fiber can rotate a certain angle without breaking, processing performance, high yield.

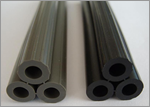

5. Pipe, hose

Good oil resistance, low temperature flexibility, resistance to bending and heat resistance make TPEE into the hydraulic and pneumatic tubes, and the preferred hose material. At the same time out of TPEE also has good processing properties, compared with other products, can be carried out with higher speed, and easy to control size.

6. Industrial Supplies

TPEE back with amazing resilience, superior toughness and strength, to creep, impact and flex fatigue resistance with a high resistance, low temperature to maintain its elasticity, and in the high temperature mechanical properties are still good, resistant to oil, fuel , solvents and various chemicals. They have been widely used in railway track pad, lift slide, chemical equipment valve seal, drive and idler belts, gears, shock and noise absorption connections and other industrial supplies.

7. Consumer Goods

TPEE in such excellent performance with high resilience, while also providing a good soft touch feel, and the PC, PVC, ABS, PBT, PET and other plastics with good adhesion and polarity, and thus in home appliances, cosmetics, tools and other Japanese widely used by consumer goods.

1. Auto Parts

TPEE has excellent resistance to (hot) oil, excellent (high temperature) curve flex fatigue performance, wear resistance, high strength and high toughness.

TPEE produced by various types of car parts with a flexible system of rubber parts is more than excellent performance, the higher temperature levels, better low temperature properties, especially the fatigue performance of TPEE other elastomers can not match.

Mainly used in auto parts: CVJ dust cover, ball dust cover, cantilever jacket, tie and jacket, and other dust cover jacket; ball wrist; air hose (engine intake air duct) airbags, seat belts department (distribution) parts, auto headlamps, auto door locks, satellite antenna clamp, door seals, shock by grinding plate, muffler gear, stopper, plug, window seat shock absorber, reducing shock chassis, chassis stoning-resistant coatings.

|

|

|

Excellent aging resistance and at low temperature physical properties of good performance, so TPEE been widely used in electrical and electronic industries, such as: wireless communications equipment antennas jacket, muffler gear drive system, electric soft cover, remote control buttons, etc. .

|

|

|

TPEE in a wide temperature range to achieve a good balance between strength and flexibility, and excellent impact resistance, fatigue resistance and UV resistance, making it very suitable for the production of ski cover, ski boot straps, golf ball and other sports equipment

|

TPEE for fiber-optic cable system is mainly manifested in the flexibility and high tear strength, chemical resistance, heat resistance, flame retardant, easy to dye, to seal from dust and liquid long-term role. TPEE has excellent tear strength, the fiber can rotate a certain angle without breaking, processing performance, high yield.

|

|

|

Good oil resistance, low temperature flexibility, resistance to bending and heat resistance make TPEE into the hydraulic and pneumatic tubes, and the preferred hose material. At the same time out of TPEE also has good processing properties, compared with other products, can be carried out with higher speed, and easy to control size.

|

|

|

TPEE back with amazing resilience, superior toughness and strength, to creep, impact and flex fatigue resistance with a high resistance, low temperature to maintain its elasticity, and in the high temperature mechanical properties are still good, resistant to oil, fuel , solvents and various chemicals. They have been widely used in railway track pad, lift slide, chemical equipment valve seal, drive and idler belts, gears, shock and noise absorption connections and other industrial supplies.

|

TPEE in such excellent performance with high resilience, while also providing a good soft touch feel, and the PC, PVC, ABS, PBT, PET and other plastics with good adhesion and polarity, and thus in home appliances, cosmetics, tools and other Japanese widely used by consumer goods.